Industry 4.0 refers to a new generation of interconnected factories, in which humans and machines work together side by side.

Sensors, robotics, business and optimization software, cloud solutions… this 4th industrial revolution is a real challenge for companies.

“Automation is more than just robots. We’re moving towards greater operational autonomy. Workflows are becoming automated, and software is automating tasks such as planning…”.

Max Blanchet, Senior Managing Director of Accenture Strategy – Head of Industry 4.0 for Europe

But how far have French companies come in terms of digitalization?

What are the challenges and opportunities?

And what about artificial intelligence, the hot topic in recent months?

3 questions that were at the heart of discussions at Investor Day 3 on October 10.

And to which Philippe Limantour (Microsoft), Akim Oural, former Chairman of Open Data France, Max Blanchet (Accenture Strategy), Fabien Laleuf (ABB) and Olivier Gibaru (Buawei) agreed to respond.

The current state of industrial digitalization in France

For a number of years, France has suffered from severe deindustrialization.

Find out more about France’s reindustrialization and its challenges

As a result of chronic underinvestment, the country’s production facilities are now getting old.

This results in:

- The obsolescence of a third of France’s industrial facilities

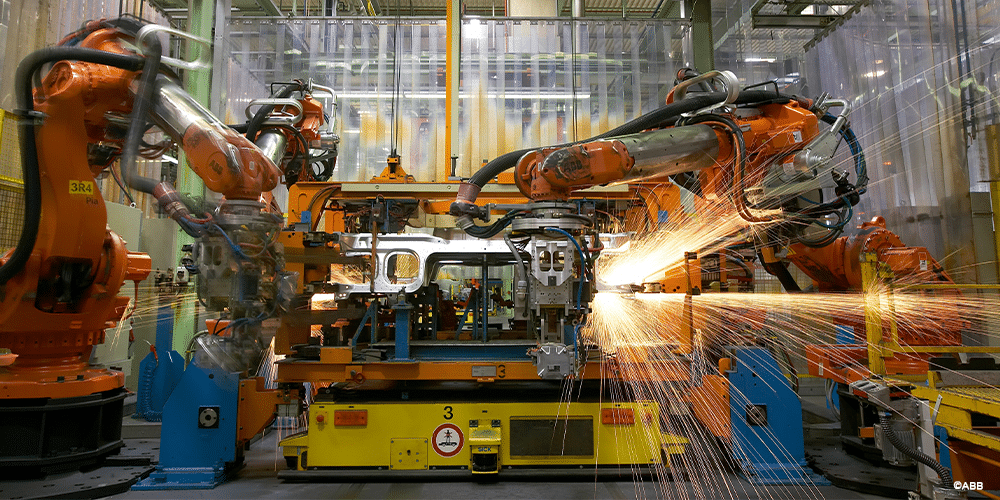

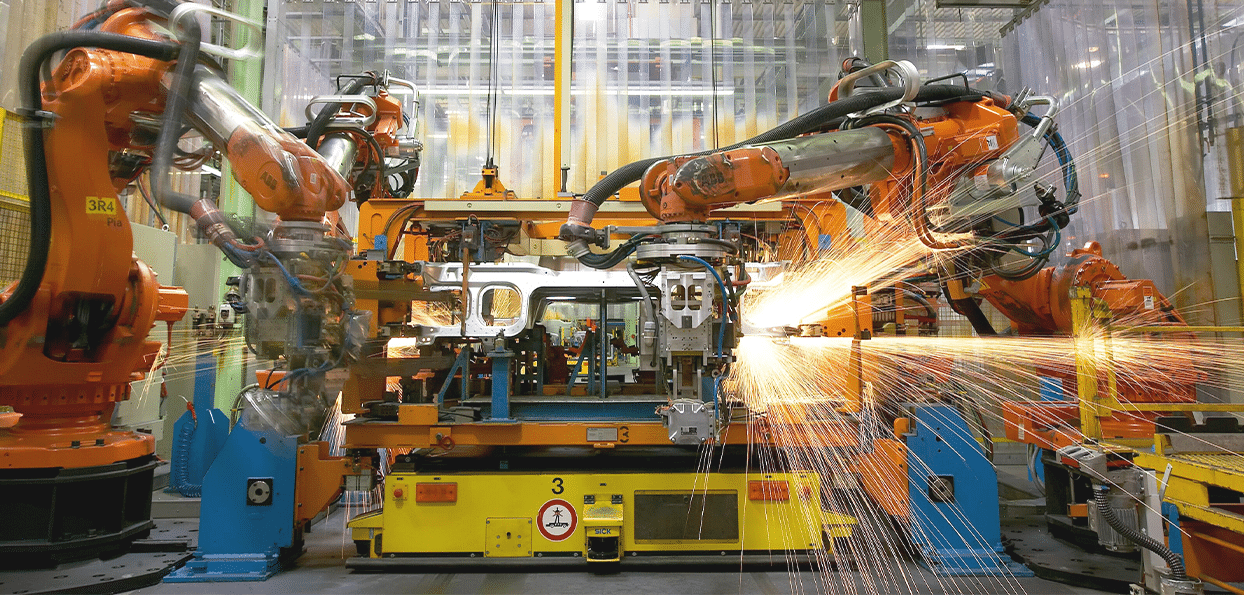

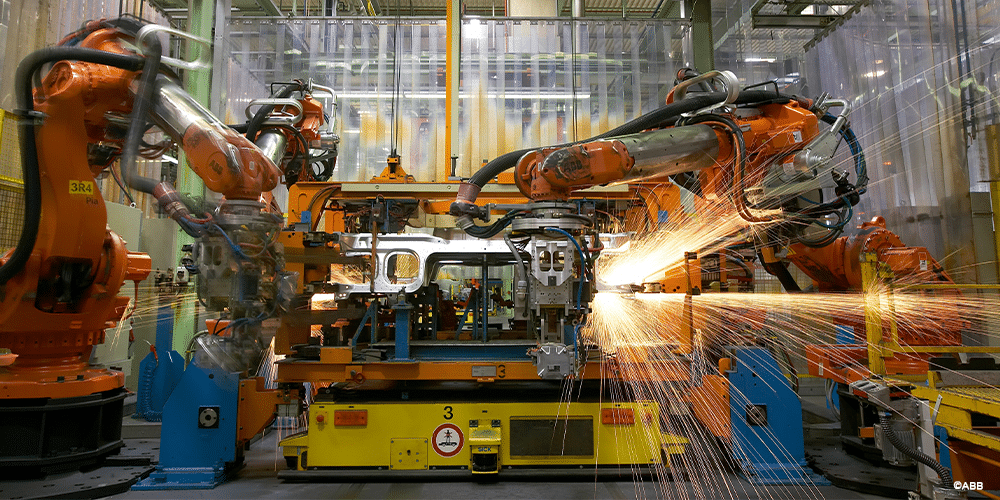

- A very low rate of robotization in our industry: 163 robots per 10,000 jobs.

Highly industrialized countries generally have a high rate of robotization.

For instance, in Korea, a champion in this field, there are 1,000 robots for every 10,000 jobs, and in China this figure rises to 322, despite an abundant, ultra-competitive workforce.

On a European scale, Germany has 397 robots, Sweden 321 and Switzerland 240.

This downward trend also reflects the negative image of robotization in France.

“France has always had an issue with robotization. Here, we think robots destroy jobs. But we’ve missed the point of competitiveness. Robotization is not a question of labor costs or staff availability. It’s a matter of competitiveness.” Fabien Laleuf, Managing Director France, ABB

In short, the country is only 48% mature in terms of the digital transformation of its businesses.

France is lagging behind and is struggling to catch up.

Industry 4.0 is moving forward, but there’s still a long way to go.

The digital shift is crucial to corporate survival. And it needs to happen now.

The gap is widening between companies that embrace digital technology and boost their competitiveness.

And the others, who are likely to exit the market in the long term.

“There’s a polarization between companies who are getting into AI, who are ahead of the game, and those who aren’t really doing so. And in 5 years, there will be a huge divide in the market” Max Blanchet, Accenture

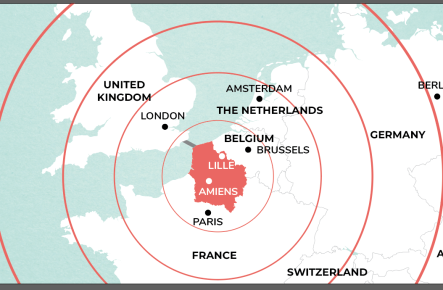

What’s the latest on digitalization in Hauts-de-France?

At 15%, Hauts-de-France’s industrialization rate is higher than the national average of 10-12%.

This represents a real development opportunity for companies in the region.

As far as robotization is concerned, ABB has 2,700 robots in the country, 60% of them in the automotive sector, with the remainder mainly at the end of the agrifood chain and in logistics.

These figures reflect the massive investments made by regional automakers and the arrival of electric mobility stakeholders.

Learn more about electric mobility in Hauts-de-France

The challenges and opportunities of digitalization for industry

Digitalization, a profound corporate transformation

Digitizing companies is a complex process.

It requires a complete reassessment of the company’s operations: business model, professions, corporate culture, processes…

Some companies develop tools, but don’t actually deploy them.

“Companies have been experimenting a lot but are now struggling to scale up. In other words, the deployment of digital technology throughout the company. This is a much more complex task, which requires investment, high-quality, well-structured data, and a level of maturity that few companies have today. ” Max Blanchet, Accenture

It is this milestone that will enable companies to reap the full benefits of this transition and generate a positive return on investment.

To do so, companies need a clear strategy, based on 4 main pillars:

- Processes: digitization means adapting workflows, working methods and processes – some of which have been around for a long time – from one end of the production chain to the other.

- Business model: the implementation of connected objects during production enables companies to collect a wealth of data. It is essential to capitalize on the latter in order to upgrade business models. Companies could then diversify their offering, which would no longer focus solely on the production of “raw” products:

- From mass production to mass customization

- Develop product-related services: the introduction of systems such as IoT enables manufacturers to analyze products throughout their life cycle and offer predictive maintenance or complementary services.

- Sell product expertise: companies that have successfully implemented highly sophisticated processes can now sell their advice to their peers.

- Sell solutions developed in-house to other companies

- Organization: a company’s digital transition involves all departments, not just production. Marketing, accounting, human resources, logistics, after-sales service…

- Corporate culture: digitizing a company is a major change for its employees and stakeholders. It has to be explained and quickly accepted by everyone, otherwise the transition will fail.

If implemented correctly, the digital transition represents great opportunities and a vector for growth and competitiveness.

The benefits of digital transformation in industry

Digital transformation brings many benefits.

- Performance: by measuring, predicting breakdowns, making better use of raw materials, integrating data… production management and monitoring tools are now essential for effective company management.

- Agility and resilience: digital technology enables us to act quickly in the event of a crisis (detection of the cause, reconfiguration, adjustment of the action plan from supplier to end customer), and to measure the impact of these changes. This reactivity also enables us to seize opportunities more quickly!

- Decarbonization: not only in terms of measuring and adjusting energy expenditure, but above all in an eco-design approach, production with optimized, carbon-efficient processes.

“SKF is trying to be part of this transition in order to offer its customers the most neutral and efficient solutions possible. To do this, it’s necessary to think in terms of eco-design, throughout the product’s entire life cycle.

For aeronautical bearings produced in Valenciennes, we work on various aspects such as weight and speed, materials, longer maintenance intervals, reconditioning…”. Vincent Mégret, General Manager, SKF France

It lies at the heart of corporate strategies. Find out how decarbonization is a competitive factor. Read the article.

- Recruitment: digitalization makes factories more attractive. For, as Max Blanchet points out, “how do you attract young talents who are familiar with chat GPT and who come to an industry where the average machine is 19 years old in France? ” It can also compensate for the loss of skills, thanks in particular to AI learning.

” Industry was founded on experience. People who were 20 or 30 years old and now know the machines like the back of their hand. How do you replace them? Not with young people who change companies very quickly. ” Max Blanchet, Accenture

- Enhanced customer experience: optimized communication channels, product traceability and improved processes enable us to personalize our offer right from the product selection stage, providing smoother service and real-time information…

- Added value: automating certain repetitive tasks saves employees time, allowing them to concentrate on more valuable tasks.

” For instance, we can use robots to help operators with strained skills, such as welders, who rather than spending half their time bringing parts to their welding table, will spend 80% of their time welding. “Fabien Laleuf, ABB

It’s a differentiating factor that will have a direct impact on a company’s productivity, competitiveness and capacity for innovation.

“You can’t reindustrialize a country like France with operations that are carried out elsewhere at low cost, on depreciated machinery. It’s all about adding value. ” Max Blanchet, Accenture

In an increasingly competitive global environment, companies must no longer capitalize on price, but on the quality of their products and services and their differentiating assets.

“Perhaps tomorrow we’ll move towards a functionality economy* and prices based on performance, rather than transactions. What savings can I bring you with my bearings and pay me for the savings achieved rather than for the intrinsic value of the product cost ” Vincent Mégret, Managing Director, SKF France

*The functionality economy is an approach in which the notion of using goods replaces that of selling them.

The specific case of AI

Digital transition means AI integration.

Today, many organizations use artificial intelligence.

Although there has been a massive uptake and adoption of conversational AI such as Chat GPT in recent months, its application in industry is much broader: camera-assisted sensing (like Buawai), virtual assistants, predictive maintenance, the Internet of Things (IoT)…

What is AI?

According to Philippe Limantour, Microsoft’s Director of Cybersecurity Technology, AI is “software that processes digital data using a pre-trained statistical model.”

The main characteristic of AI is its ability to learn.

Thanks to it, machines are able to perceive, understand, act and learn as they calculate via :

- Machine learning, which involves training computers to learn like humans in order to carry out defined actions.

- Deep learning, which enables machines to learn without human intervention, based solely on data.

There are 3 types of artificial intelligence:

- Weak (or narrow): simple business algorithms, based on machine learning

- Strong: Generative AI that learns and tries to reproduce human thought (like Chat GPT), based on deep learning.

- Super artificial intelligence: utopian for now, superior to humans and able to feel emotions.

“Until 6 months ago, we never had a machine that understood us in this way. For 60 years, men and women had to learn how to use a keyboard, a mouse… It often takes months to master a software program. Now, we can converse with it” Philippe Limantour, Microsoft France

The challenges of AI

When properly handled, artificial intelligence has incredible potential and represents a major step forward for society, particularly in terms of accessibility.

It simplifies understanding (complex documents, software…) and revolutionizes learning methods and speed.

“It used to take 6 months or a year to master a software program. Today, with AI, we no longer need those 6-8 months of training. We talk to the software that will interface with the complexity, which will simplify the process.” Philippe Limantour, Microsoft

However, it faces 2 major challenges:

- Ethics and responsibilityAlthough it learns as it goes along, the machine was originally programmed by Man, whose biases it can be led to reproduce.

Since it lacks a conscience in the strict sense of the word, it may be led to make discriminatory or abusive decisions.In the corporate context, it’s important to be able to explain the decision-making process, to have checkpoints and to correct potential errors or biases.

- Personal and confidential data securityAI receives, analyzes and compiles an exponential amount of data, some of which is sensitive.It is therefore essential for companies to store this data in secure locations using powerful security protocols.

“It takes 1h12 for an attacker to penetrate the defenses of one machine and then spread to the rest of the computer. And companies often take months to realize this. ” Philippe Limantour, Microsoft

The need for responsible AI

AI is becoming increasingly important in both our personal and professional lives.

And its capabilities have not yet reached their peak.

Most of today’s binary-based models are very powerful.

Tomorrow, with the arrival of quantum computing, the capacity of these systems will be multiplied by 30, according to Akim Ural, former Chairman of Open Data France.

“Before, we used technology for support. With quantum, technology will lead the way. This requires regulation now, in order to avoid legislating after the fact. ” Akim Ural

Various actions can also be put in place to counter the major risks of AI:

- Open AI source code and data transparency: in order to understand how the algorithm works, ensure compatibility with European and French regulations and guarantee the security of the information provided.

- Data storage in France: in order to guarantee security

“I believe that data should be stored close to home, particularly as regards the public domain, so as to protect it from attack” Akim Oural, Former President of Open Data France

- The implementation of human controls, as Microsoft is doing through “Microsoft research”, a group made up of different profiles (researchers, sociologists, ethnologists, etc.). “who are working on what the development of a responsible AI framework can be, from the very beginning of the idea all the way to execution”. Philippe Limantour

The most important lever is still education and training.

“The implementation of this new technology in our society is inevitable. So, education is needed. The more we educate people about the impact of AI on our society and daily lives, the more we will enlighten their opinions and the more we will enable everyone not to be slaves to new technologies” Akim Ural

In conclusion, the survival of companies is now linked to their capacity for digital transformation.

As we have just seen, industrial digitalization is revolutionizing the way companies operate in France and around the world.

This digital transformation, far from being a mere trend, has become a necessity if we want to remain competitive in the marketplace.

Companies that fully embrace this digital revolution will open the doors to a new era: one of increased operational efficiency, improved product quality, personalized services, and reduced costs.

And artificial intelligence (AI) plays a central role in this transformation.

It offers unprecedented opportunities to automate processes, make decisions based on accurate real-time data, deliver exceptional customer experiences, and give employees more time to work on value-added tasks.

However, this digitization must take place within the framework of stringent French and European regulations, in order to guarantee accountability, data security and process transparency.

Digitizing industries will be costly and will require great flexibility on the part of companies.

They will need to continually adapt to new technologies, market trends and changing customer expectations.

But those who don’t do so today run the risk of no longer existing in a few years’ time.

“The development of Industry 4.0 is a unique opportunity to fully reconcile technology and the ecological transition, in the interests of creating more skilled jobs and improving business competitiveness. “ Fabien Laleuf, Managing Director France, ABB

Do you have a development project in Hauts-de-France?

Tell us about your project!