2. The introduction of green energy

To reduce dependence on fossil fuels, companies can make use of renewable and recovered energies.

“A project to transform our processes was validated by the European Commission this summer. At ArcelorMittal, CO2 is primarily emitted by our blast furnaces. We would like to replace one of these blast furnaces with a DRI*, which would allow us to replace the use of coal with natural gas and then hydrogen when it becomes available. We could thus reduce our CO2 impact by 36%” Thierry Flament, ArcelorMittal

*DRI = direct reduction of iron. This technology has great potential for reducing CO2 emissions. It is one of ArcelorMittal’s three decarbonization routes.

3. Recycling and circularity

Using recycled materials reduces the need for raw materials.

A need shared by several speakers at Investor Day 3.

“We have invested €60 million in steel circularity. We want to find better ways of reusing steel, which is a product that can be recycled indefinitely. This would allow us to achieve an 8% reduction in CO2 emissions” Thierry Flament, ArcelorMittal

“For SKF, remanufacturing and recycling bearings are key to the future of aerospace. This represents a major investment, and the sector is still in its infancy.

When we recondition a bearing, the ecological balance is -90% in terms of the CO2 footprint. ” Vincent Mégret, SKF

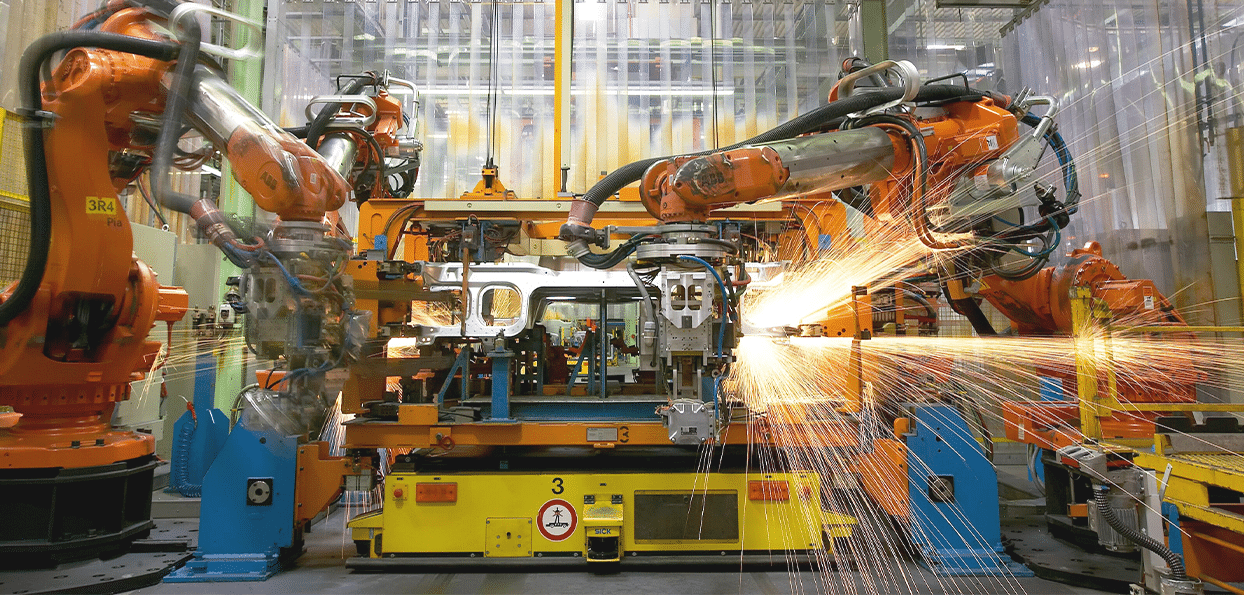

4. The modernization and digitalization of production facilities

France’s industrial park is aging.

To ensure energy efficiency, it is essential to invest in production facilities.

“The development of Industry 4.0 is a unique opportunity to fully reconcile technology and the ecological transition, in the interests of creating more skilled jobs and improving business competitiveness. “ Fabien Laleuf, Managing Director France, ABB

5. An informed choice of suppliers

A company’s scopes 2 and 3 are the most difficult to turn green.

That’s why it’s essential to choose the right suppliers and subcontractors.

Some companies now prefer to choose:

- Low carbon footprint suppliers

“At SKF, we strive to make the entire product value chain greener. The decarbonization challenge for manufacturers focuses on scope 3, which accounts for almost 80% of greenhouse gas emissions. By working on greener production, SKF is helping to reduce the carbon footprint of its customers’ end products” Vincent Mégret, SKF

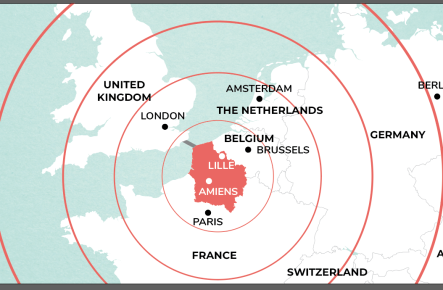

- Suppliers close to home, and who work as locally as possible

“In our industrial development policy, we give priority to proximity with the main sources of supply for batteries or production waste, in order to limit the environmental impact of transport. That’s why the Hauts-de-France region is so strategic for us, and the location of Harnes particularly advantageous. ” Alessandro Tripoli, Li-Cycle

Like Li-Cycle, the location of your future plant is crucial.

🔎 Discover the risks of making the wrong choice for your project.

6. Shared investments

Faced with sometimes colossal financial requirements, some companies choose to pool their equipment or investments.

“All the synergies we can achieve in the region are important, because we’re not the only manufacturers to have this problem. This allows us to have a global vision to share investments and solutions for this co2 capture” Thierry Flament, ArcelorMittal